From Photovoltaic Panels To Inverters: A Detailed Explanation Of The Composition Of a Complete Solar Power Generation System

Against the backdrop of global advocacy of sustainable energy, solar energy, as a clean and renewable energy source, is gradually entering our lives. Solar power generation systems have attracted more and more attention for their environmental protection, energy saving and many other advantages. So, how is a complete solar power generation system composed? Let's start with the most basic component - photovoltaic panels.

Photovoltaic panels: "capture" of solar energy

Photovoltaic panels, also known as solar panels, are one of the core components of solar power generation systems. They act like an efficient "capture" responsible for converting sunlight into electrical energy. Its working principle is based on the famous "photovoltaic effect". When sunlight shines on a photovoltaic panel, photons interact with the semiconductor material in the photovoltaic panel to stimulate electron-hole pairs. These electrons and holes move in different directions under the action of the electric field inside the semiconductor material, forming an electric current.

Photovoltaic panels are usually composed of multiple solar cell units. Most of these cell units are made of silicon materials, of which monocrystalline silicon cells and polycrystalline silicon cells are the most common. Monocrystalline silicon cells have a high conversion efficiency, generally reaching 20% - 25%, which means that it can convert 20% - 25% of the solar energy into electrical energy. Its manufacturing process is relatively complex and the cost is relatively high, but it has stable power generation performance and a long service life of up to 25 - 30 years. The conversion efficiency of polycrystalline silicon cells is slightly lower, about 15% - 20%, but its production cost is relatively low, and it has certain cost-effectiveness advantages in large-scale applications, and its service life can also reach about 20 - 25 years.

In addition to monocrystalline silicon and polycrystalline silicon cells, there are other types of photovoltaic panels such as amorphous silicon, cadmium telluride, and copper indium gallium selenide. Amorphous silicon photovoltaic panels have the advantages of good flexibility and can be made into thin films. They are often used in some scenes with special requirements for appearance or installation space, but their conversion efficiency is relatively low, generally 6% - 12%. Cadmium telluride and copper indium gallium selenide photovoltaic panels have certain potential in conversion efficiency and cost, and have developed rapidly in recent years, but their market share is still lower than that of monocrystalline silicon and polycrystalline silicon photovoltaic panels.

Inverter: "Converter" from DC to AC

The power generated by photovoltaic panels is DC, while most of the electrical appliances we use in our daily lives require AC to work properly. At this time, the inverter plays a key role. It is like a magical "converter" responsible for converting the DC output of photovoltaic panels into AC to meet the power needs of different users such as families and enterprises.

There are many types of inverters, and the common ones are centralized inverters, string inverters and micro inverters. Centralized inverters have high power and are generally suitable for large solar power stations. It collects the DC generated by multiple photovoltaic panel groups and converts them. The advantage is that the cost is relatively low and it is easy to centrally manage and maintain, but once a fault occurs, it may affect the operation of the entire power generation system. The string inverter converts DC to AC separately for different photovoltaic panel groups, and then aggregates these AC. It has higher flexibility. Even if a certain string has problems, it will not affect the normal operation of other strings. In addition, it can better play its performance advantages in the installation scenarios of photovoltaic panels with partial shielding or different orientations. It is currently widely used in distributed photovoltaic power generation projects. The micro inverter is directly installed on the back of each photovoltaic panel to convert the DC power output of each photovoltaic panel separately. Its biggest feature is that it can realize independent monitoring and maximum power point tracking of each photovoltaic panel. Even if a photovoltaic panel is blocked or fails, other photovoltaic panels can still work normally, which greatly improves the power generation efficiency and stability of the entire power generation system. However, since each micro inverter only corresponds to one photovoltaic panel, its cost is relatively high.

In the process of converting electric energy, the inverter also has some other important functions. For example, the maximum power point tracking (MPPT) function can monitor the output power of the photovoltaic panel in real time and automatically adjust the working parameters so that the photovoltaic panel always works near the maximum power point, thereby improving the power generation efficiency. In addition, the inverter also has safety protection functions such as overvoltage protection, overcurrent protection, and leakage protection to ensure the stable operation of the power generation system and the safety of personnel and equipment.

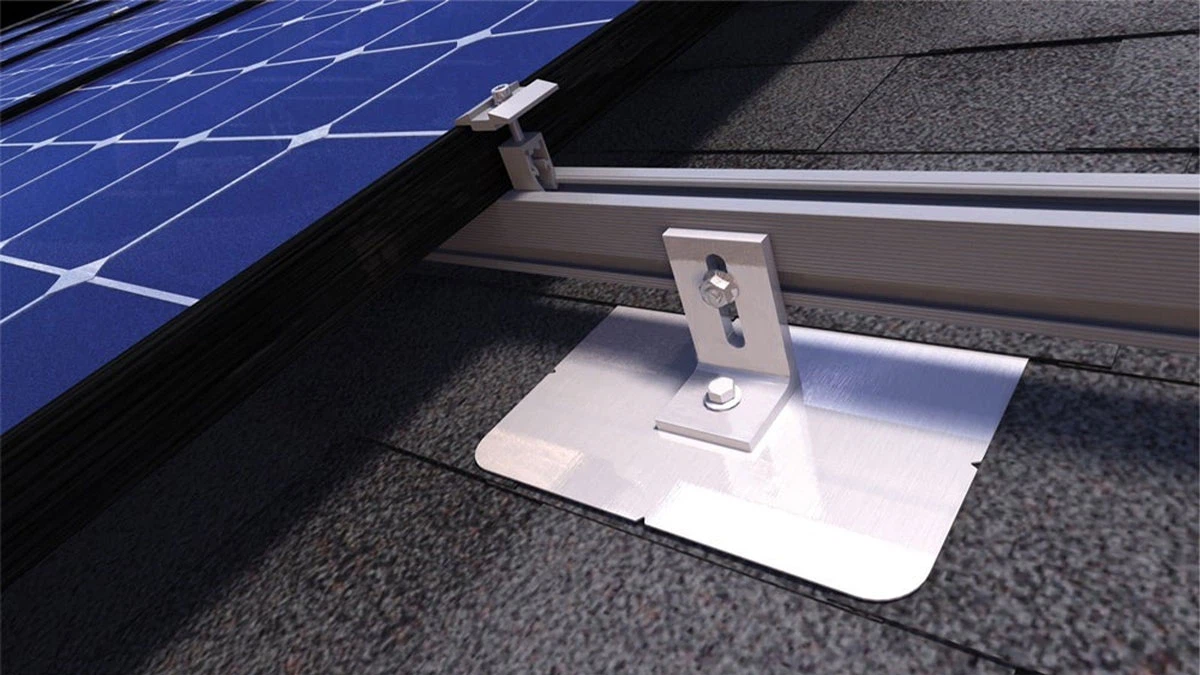

PBracket system: "stable support" for photovoltaic panels

In order for photovoltaic panels to better receive sunlight, a stable support structure is needed, which is the bracket system. The bracket system is like a "solid backing" for photovoltaic panels. It not only bears the weight of the photovoltaic panels themselves, but also resists various natural environmental factors, such as wind, rain, snow, etc.

Bracket systems can be divided into two types: fixed and tracking. Fixed brackets are simple to install and low in cost. They fix photovoltaic panels on the ground, roof or other buildings at a certain angle and orientation. The installation angle of this bracket is usually optimized according to the local latitude and solar radiation conditions to ensure that photovoltaic panels can receive sufficient sunlight for most of the year. Tracking brackets are more intelligent. They can automatically adjust the angle of photovoltaic panels according to the changes in the position of the sun, so that photovoltaic panels always remain perpendicular or nearly perpendicular to the sunlight, thereby maximizing the efficiency of photovoltaic panels receiving sunlight. Tracking brackets are generally divided into two types: single-axis tracking and dual-axis tracking. Single-axis tracking brackets can rotate along one axis (usually the horizontal axis in the east-west direction or the inclined axis in the north-south direction), while dual-axis tracking brackets can rotate simultaneously in two axes, with higher tracking accuracy, but relatively higher costs.

When choosing a bracket system, many factors need to be considered comprehensively. For example, the topography of the installation site, the available area, local climate conditions, and budget. For small distributed photovoltaic power generation projects, such as household rooftop photovoltaic systems, fixed brackets are usually selected due to limited installation area and cost sensitivity. In large ground photovoltaic power stations, if site conditions permit and higher power generation efficiency is sought, tracking brackets may be a better choice.

Battery pack: "Storage warehouse" of electric energy

In solar power generation systems, battery packs play the role of "storage warehouse" of electric energy. When there is sufficient sunlight, the electricity generated by photovoltaic panels can be used by users immediately, and the excess electricity can be stored in the battery pack. In the case of insufficient sunlight at night or on cloudy days, the battery pack releases the stored electricity to provide users with a continuous and stable power supply.

Common types of batteries include lead-acid batteries, nickel-metal hydride batteries, and lithium-ion batteries. Lead-acid batteries are one of the most widely used energy storage batteries. They have the advantages of low cost, mature technology, and easy maintenance. However, their energy density is relatively low, their volume and weight are large, and their charge and discharge cycle life is generally around 300-500 times. The performance of nickel-metal hydride batteries is better than that of lead-acid batteries. They have higher energy density, longer charge and discharge cycle life (up to about 1,000 times), and are environmentally friendly, but their cost is also relatively high. Lithium-ion batteries have significant advantages such as high energy density, small volume, light weight, high charge and discharge efficiency, and long cycle life (usually up to 1,500-3,000 times), but their cost is relatively high at present. In some cost-sensitive application scenarios, their promotion is subject to certain restrictions.

When designing and configuring battery packs, it is necessary to comprehensively consider factors such as the actual power demand of the solar power generation system, the power generation capacity of the photovoltaic panels, and the local light conditions. For example, it is necessary to determine the appropriate battery capacity to ensure that the basic electricity demand of users can be met in the case of continuous cloudy days. At the same time, it is also necessary to pay attention to the charge and discharge management of the battery, adopt a reasonable charge and discharge strategy, extend the service life of the battery, and reduce the cost of energy storage.

Controller: The "smart housekeeper" of the power generation system

The controller is the "smart housekeeper" of the solar power generation system. It is responsible for monitoring and controlling the entire power generation system to ensure the safe and stable operation of the system. The controller mainly has the following important functions:

The first is the charge and discharge control function. It can monitor the voltage, current and other parameters of the battery group in real time, and automatically control the charging process of the photovoltaic panel to the battery according to the charging status of the battery and the working conditions of the power generation system to prevent the battery from being overcharged or over-discharged. When the battery is fully charged, the controller will automatically cut off the charging circuit to avoid damage to the battery caused by overcharging; and when the battery power is too low, the controller will control to stop discharging to protect the service life of the battery.

The second is the maximum power point tracking control function. The controller can adjust the working state of the photovoltaic panel in real time by working in conjunction with the inverter, so that it always runs near the maximum power point, thereby improving the power generation efficiency of the photovoltaic panel.

In addition, the controller also has system fault diagnosis and protection functions. It can monitor each component in the power generation system in real time. Once a fault is detected, such as a short circuit in the photovoltaic panel, overheating of the inverter, leakage of the battery, etc., the controller will immediately take corresponding protection measures, such as cutting off the fault circuit and issuing an alarm signal, to ensure the safe operation of the entire power generation system and facilitate maintenance personnel to troubleshoot and repair faults in a timely manner.

The controllers used in solar power generation systems of different types and sizes are also different. In small solar power generation systems, a relatively simple integrated controller is usually used. It integrates basic functions such as charge and discharge control and maximum power point tracking control. It is small in size and low in cost, and is suitable for small application scenarios such as home rooftop photovoltaic systems. In large solar power stations, a more powerful and intelligent centralized controller is required. It can uniformly monitor and manage many photovoltaic panels, inverters, battery packs and other equipment in the entire power station to achieve more efficient and accurate system control.

A complete solar power generation system consists of multiple components such as photovoltaic panels, inverters, bracket systems, battery packs and controllers working together. Each component plays an indispensable role. They work together to convert solar energy into electricity that we can use, contributing to the realization of sustainable energy development. With the continuous advancement of technology and the gradual reduction of costs, the application prospects of solar power generation systems will be broader and are expected to occupy a more important position in the future energy field.