At our factory, we take pride in our total number of factory staff, which amounts to 335 dedicated individuals that are committed to delivering high-quality products and exceptional customer service. Our team is comprised of professionals across various departments, including design and development, manufacturing, quality testing, packaging, and transportation. Each team member is equipped with the requisite technical skills and expertise to ensure that our products are manufactured with the highest level of precision and care.

Moreover, we are proud to offer support for OEM and ODM services, which enables us to provide customized solutions that meet our customers' unique requirements. Our products are also subject to rigorous third-party testing, ensuring that they meet the highest standards of quality and safety.

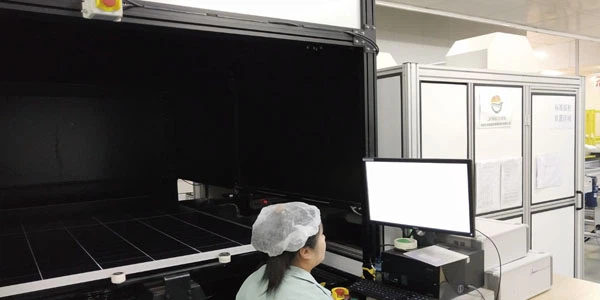

At our production facility, we are fortunate to have access to a wide range of top-of-the-line equipment. Our main production equipment includes a Laser Scribing Machine, Photovoltaic String Welder, Laminating Machine, Type-Setting Equipment, Sticking Film Machine, and a Laminating Production Line. These machines are state-of-the-art and have been carefully selected to ensure that we are able to produce high-quality and precise solar panels.

The Laser Scribing Machine allows us to accurately and easily cut through specialized materials used in the construction of our solar panels. Our Photovoltaic String Welder creates reliable connections between the solar cells. Our Laminating Machine uses a unique process to bond the individual layers of the solar panel together.

Our Type-Setting Equipment is used for the production of high-quality textual materials that are essential for panel production. The Sticking Film Machine ensures that our panels are securely fastened to maintain their structural integrity. Our Laminating Production Line allows us to increase our production capacity while maintaining the highest level of quality.

Process Description

Lithium Battery Production Process

Jingsun offers a comprehensive OEM/ODM service for customers worldwide. The manufacturing process of Jingsun lithium batteries is divided into several stages.

Firstly, raw materials, such as lithium salts, conductive carbon, and other additives, are carefully selected and inspected before being mixed into a homogenous slurry. This slurry is then coated onto copper or aluminum foil in a multi-step coating process to create the anode and cathode materials of the battery.

Secondly, the anode and cathode films are assembled together with a separator film and rolled into a cylindrical shape. The cylindrical cell is then placed into a metal can and the electrodes are connected by tabs. The can is then sealed and the cell undergoes aging to stabilize its performance.

Thirdly, the cylindrical cells are assembled into battery packs, tailored to suit specific customer requirements. Different cell configurations can be used, such as parallel or series connections, to achieve the desired voltage, capacity, and power. The cells are joined using spot welding, bus bars, or interconnects.

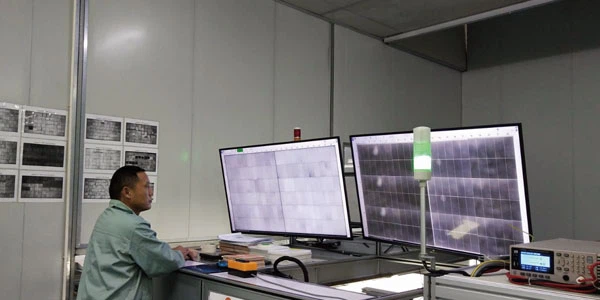

Fourthly, Jingsun performs rigorous quality control and testing throughout the production process. Each battery pack undergoes a series of tests, including electrical, mechanical, and environmental tests, to ensure its compliance with industry standards.

Finally, Jingsun offers its customers a range of customization options to meet their specific needs. These include the battery pack size and shape, output voltages, capacities, and connectors. The company also provides additional services, such as battery management systems and enclosure design.

In summary, Jingsun's lithium-ion battery production process involves raw material selection and inspection, electrode coating, cell assembly, pack construction, quality control, and customization. Its OEM/ODM service ensures that customers receive high-quality lithium batteries that meet their unique requirements.

Inverter Production Process

The production process of Jingsun inverters begins with the selection of high-quality components. The components used in the inverters include capacitors, transformers, circuit breakers, and other electronic parts.

The next step in the production process is the design of the hardware and software. The design team creates the circuit boards and software necessary for the inverters to operate smoothly. The circuit boards are designed to minimize energy loss and ensure high conversion efficiency.

Once the design is complete, the production team begins assembling the inverters. Components are carefully soldered to the circuit boards using advanced production equipment. Quality control inspections are conducted at every stage of the production process to ensure that the inverters meet strict quality standards.

After assembly, the inverters undergo rigorous testing to ensure that they perform at peak efficiency levels. The testing involves simulating different operating conditions to ensure that the inverters can withstand varying environmental factors. Inverters that pass the testing stage are transported to the packaging area.

Finally, the completed inverters are packaged and shipped to customers. Jingsun ensures that its inverters are packaged carefully to prevent damage during shipping. The company also provides installation instructions and technical support to its customers.

Overall, Jingsun's production process for inverters is characterized by a strong focus on quality and attention to detail at every stage of the process.

Packaging And Shipping

Jingsun is committed to providing high-quality packaging and transportation options for their solar energy products, including solar panels, lithium batteries, inverters, and other solar-related products. With extensive experience in the industry, Jingsun values the safety and protection of their products during transportation and takes every necessary measure to ensure they arrive at their destination in perfect condition.

For Jingsun, the packaging process starts with carefully assessing the products and identifying the appropriate packaging materials. They use high-quality materials such as bubble wrap, foam, and sturdy boxes to protect their products from damage during transportation. Additionally, they use advanced packaging technology to ensure that their products are secured and well-protected throughout the shipping process.

When it comes to transportation, Jingsun offers a variety of options to meet their clients' needs. They work with reputable logistics companies and carriers to ensure timely and efficient delivery. They also offer flexible shipping solutions such as sea, air, and land transportation, depending on the client's location and preference.

As an OEM/ODM provider, Jingsun understands the importance of custom packaging and transportation solutions to meet their clients' unique needs. They work closely with their clients to develop tailored packaging, branding, and transportation solutions to ensure their clients' products are delivered safely and on time.

Jingsun is committed to providing exceptional packaging and transportation options to ensure their clients' solar energy products are well-protected and arrive in perfect condition.

After-sales Service